MIBOX-partner van uw verpakkingsproject

The know-how of Mibox

MIBOX has more than 25 years of experience with box forming machines.

Do you have a project for which you want to fold and glue cardboard packaging? Our MIBOX team is happy to put our experience and know-how at your disposal to advise you on the best technical choices for setting up the cardboard. Make the right choices for efficient and cost-effective production, together with us. We’ll help you think about developing a full line of box forming that is perfect to set up with low maintenance and minimal production stops.

MIBOX gives you the support and advice for your project in combination with the best case forming machines on the market in terms of reliability and productivity.

Discover the most common types of cardboard boxes on this page, such as cardboard box with sidewalks, stacking edges with folded edges, cardboard trays with half-rolled corners, but also easy-to-stack conical cardboard trays, 4-point glued trays, cardboard boxes with reinforced sides, cardboard displays (PAV) “ready-to sell” (POS), etc …

MIBOX means; “tailored”. Contact them and challenge them. They are there to advise you on the best model adapted to your limitations. Their 25 years of experience is at your service!

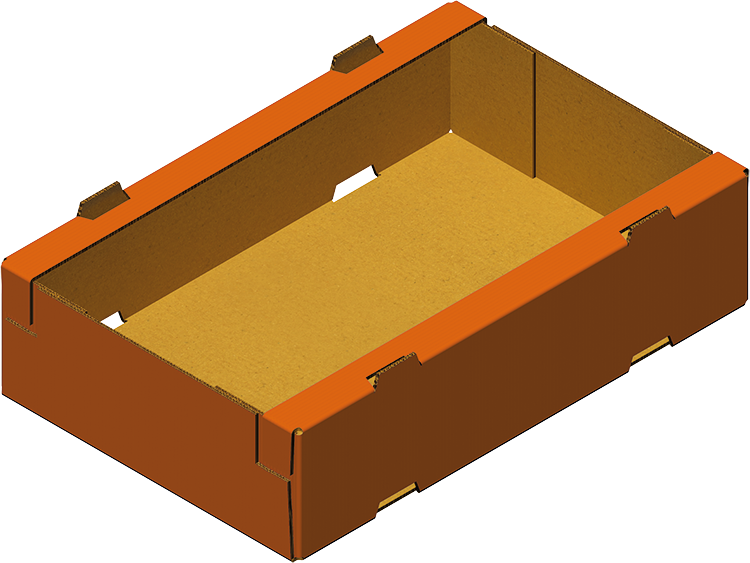

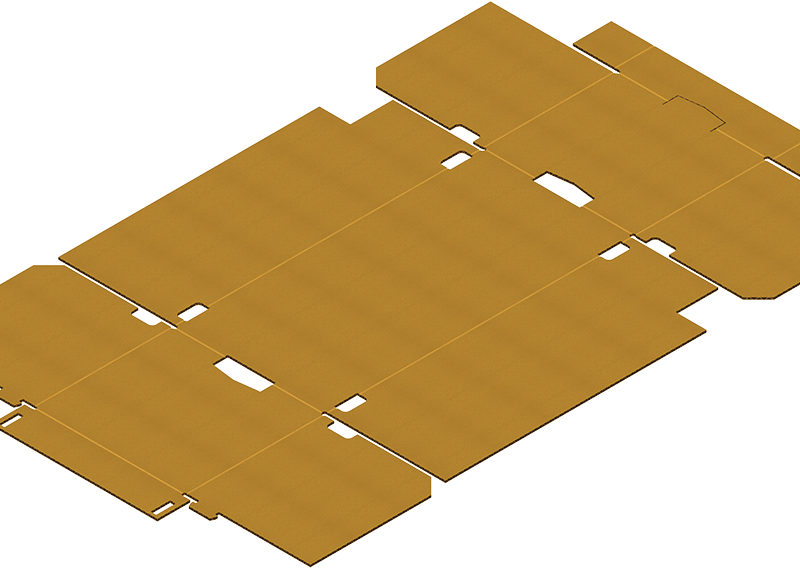

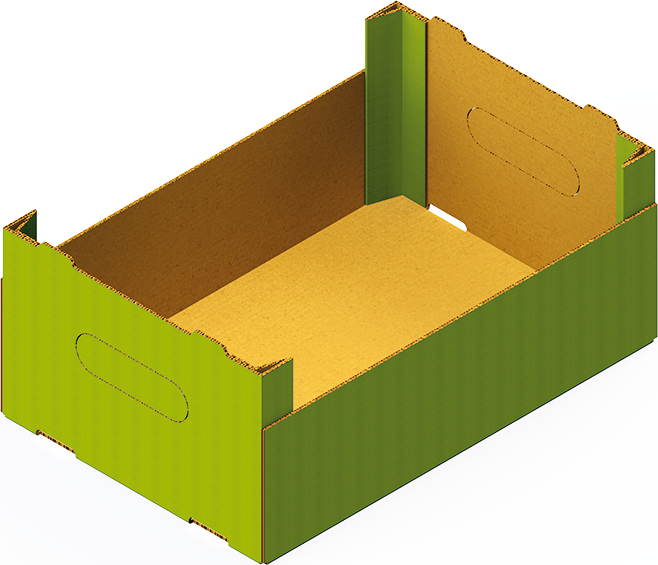

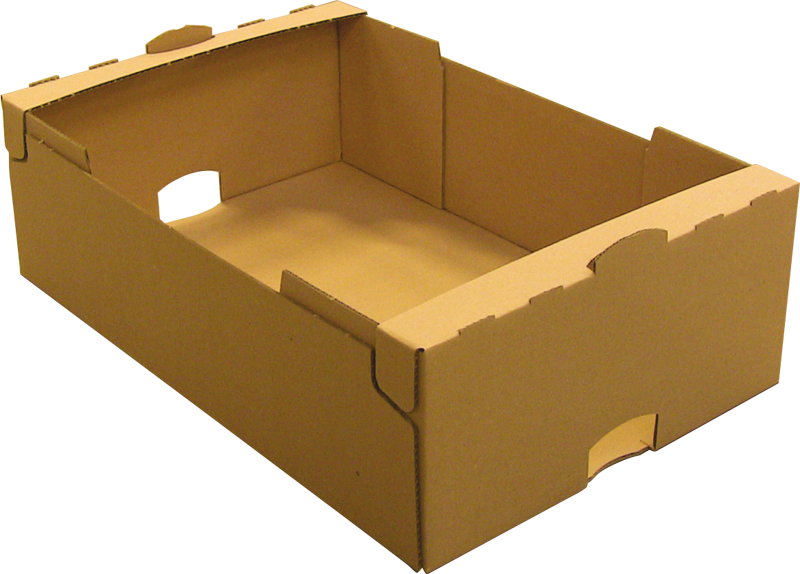

4-point glued tray with turned sides

4-point glued tray with folded sides, suitable for stacking. Made with the MIBOX B30.

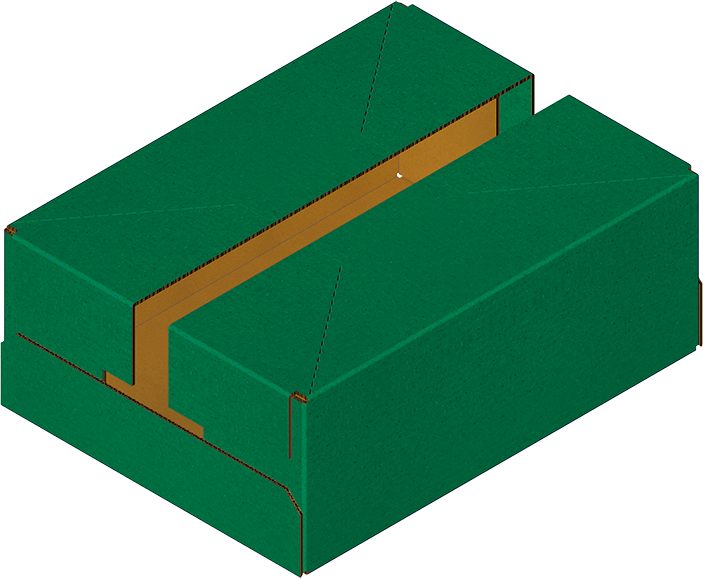

4-point glued tray with two half lids

4-point glued tray with two half lids / flaps: cardboard box that is closed mechanically or manually by means of two ½ lids (snap-on). Four-point glued trays are formed and glued with the MIBOX B30 case erector

4-point glued tray with display function on the long side

4-point glued tray with display side: function for visualizing the products on the shelves of the supermarket. This glued tray can be set up by, for example, the MIBOX B30H

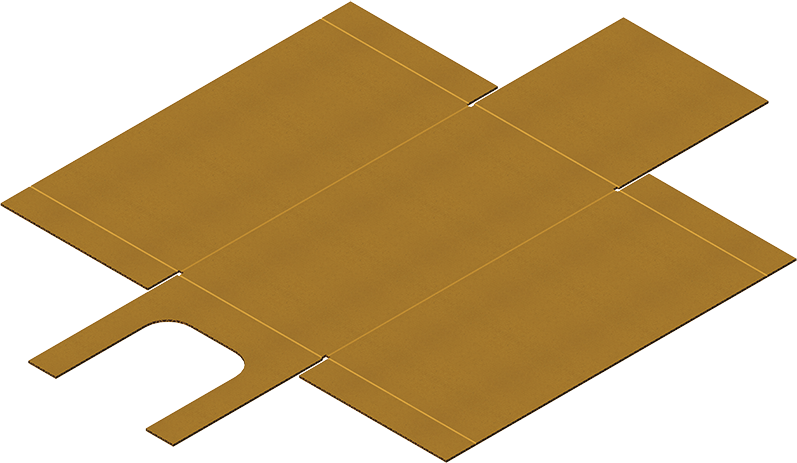

Display tray. Ready for sale. (RFS)

Ready For Sale tray (RFS) or display tray: shaped like a normal box, after dividing the tray in half, it becomes a commercial display. This box can be folded and glued with the MIBOX T30 box erector.

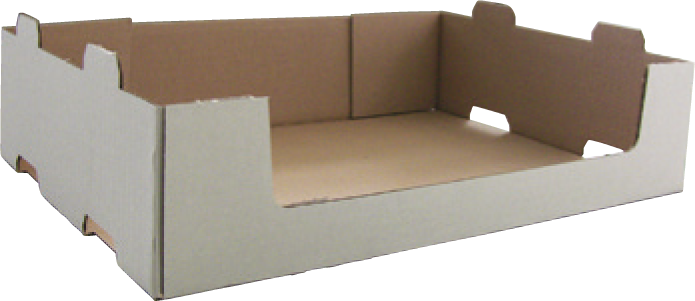

Tray with stacking edges (sidewalks)

Tray with stacking edges and glued “ears”. The most common model. Can be set up on, for example, the MIBOX T30 case erector

Tray with stacking edges and with turned sides

Tray with sidewalks with turned sides; strong stackable tray. Can be produced with the MIBOX T30H tray forming machine

Tray with one glued stacking edge and one for mechanical closure

Tray with one glued stacking edge and one for mechanical closure. (Snap-on). used for simple insertion of products that cannot simply be placed under a stacking edge, if they are already closed. Possible with the MIBOX T30 tray forming machine

Conical tray

Conical tray; for light products, efficient in cardboard use and stackable. Can be processed with the MIBOX D20H tray forming machine

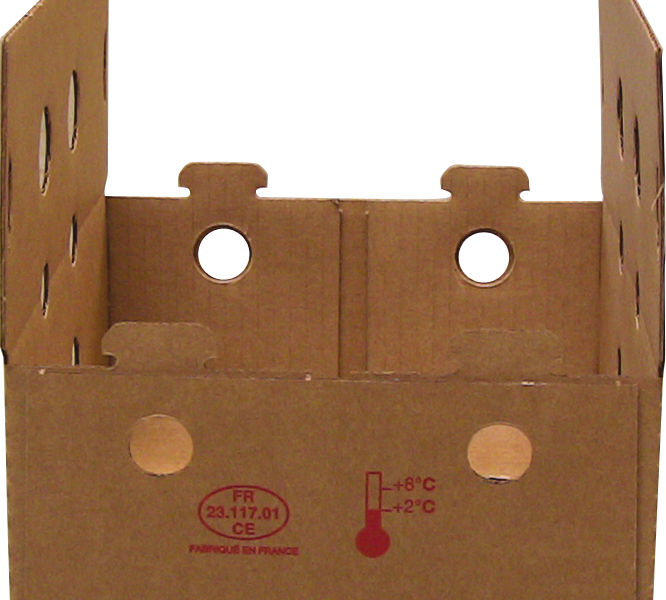

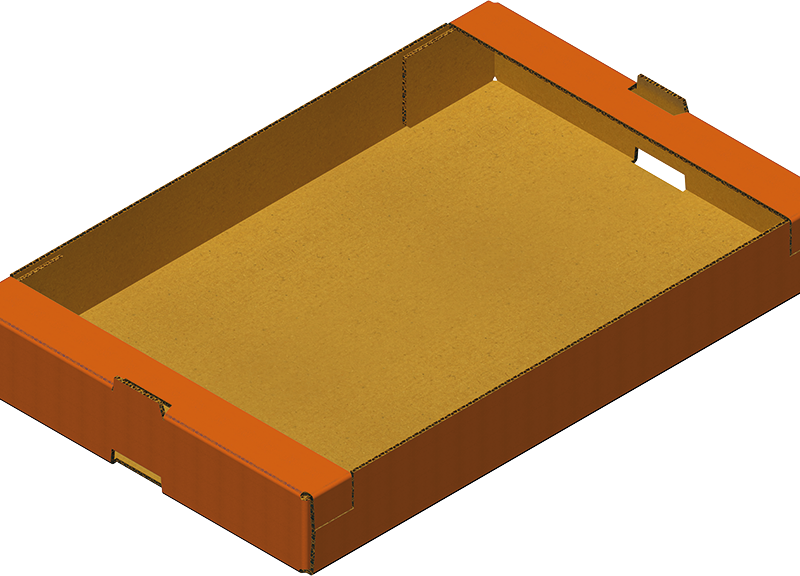

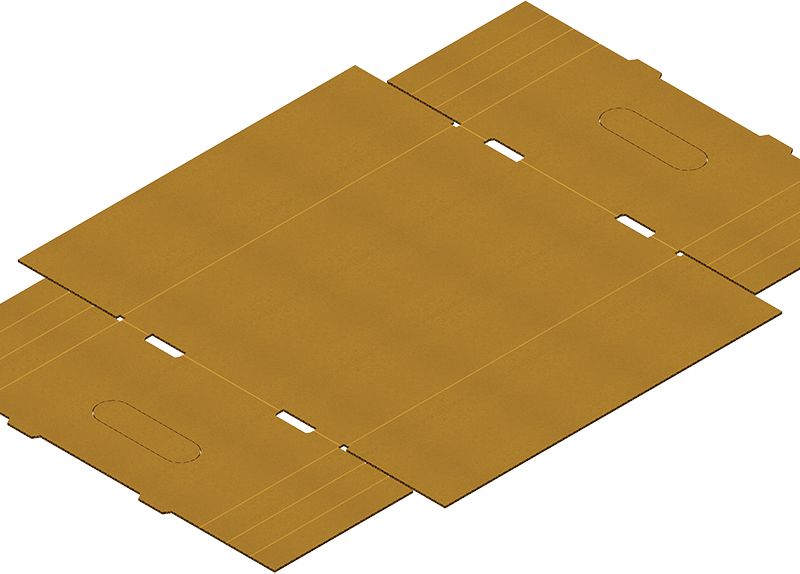

Tray with reinforced half rolled-in corners

Tray with reinforced half rolled-in corners; is most efficient in carton usage and compression value. Can be set up with the tray forming machine MIBOX D20